Chicken Wire Mesh

Cost effective, high quality chicken wire mesh.

Use for small animal enclosures, chicken coops, fruit cages, general gardening & DIY applications.

Choose from ECONOMY, STANDARD or SUPER grades to suit all budgets and needs. Learn more here.

Key info:

- Hexagonal mesh in range of sizes

- Galvanised steel – rust protection

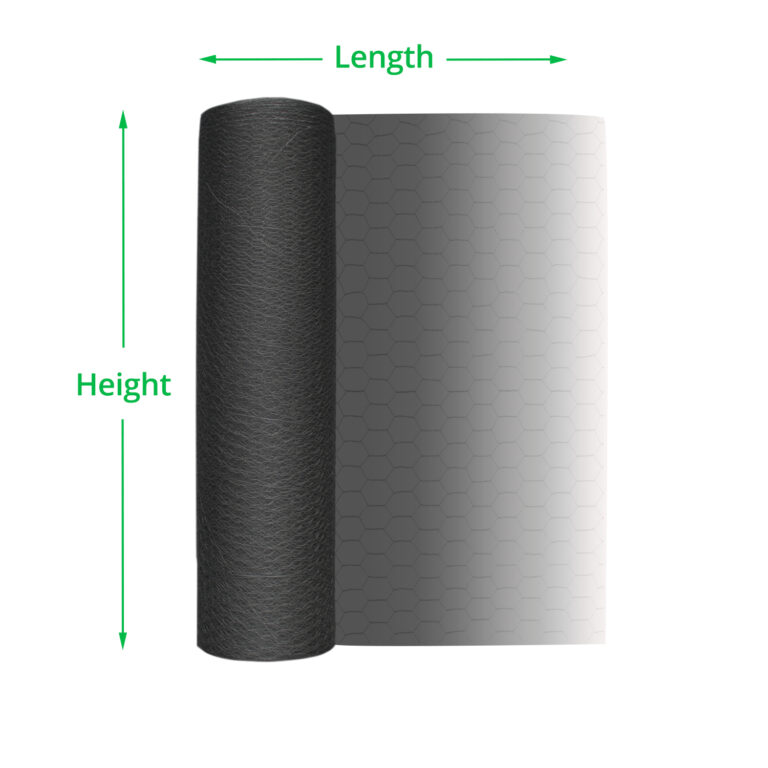

- Delivered as a roll

- Lightweight, easy to unravel

- Easy to cut & shape

Related: PVC Chicken Wire, All Wire Mesh & Netting

Customer Images

Product Information: Chicken Wire Mesh

Grading

| Type | Galvanisation Method | Properties |

| ECONOMY |

Steel wires are pre-galvanised before being woven together to create the netting. |

Thinner coating. Lower abrasion & corrosion resistance. |

| STANDARD | Mesh is manufactured, then hot dip galvanised in a protective zinc layer. | Thicker, continual coating in all areas, higher strength, higher abrasion & corrosion resistance. |

|

SUPER |

Mesh is manufactured, then hot dip galvanised in a thicker protective zinc layer. |

Best quality for professional use. Increased abrasion & corrosion resistance to withstand harsh conditions, incl. beneath the soil. Long lifespan. |

Size & Applications

| Mesh Size | Available In: | Use For: |

| 13mm x 13mm | Economy & Standard | Fruit cages / Bird protection / Keeping out squirrels and larger rodents |

| 25mm x 25mm | Economy & Standard | Chicken runs / Bird proofing / Fencing / Plastering / Floor screeding |

| 31mm x 31mm | Economy / Standard / Super | Rabbit protection |

| 50mm x 50mm | Economy / Standard / Super | Chicken coops / Poultry enclosures / General purpose / Fencing |

Properties

| Property | Description |

| Material & Construction | Galvanised steel, hexagonal fencing mesh. Hot dipped in protective zinc coating |

| Appearance | Hexagonal apertures. Metallic grey, silver look |

| Handling | Lightweight & malleable. Easy to cut & shape |

| Biodegradable | No |

| Protecting exposed steel | Rust may occur where new cuts are made if untreated steel is exposed. Protect with galvanised spray or paint |

| Not suitable for… |

|

Installation Instructions

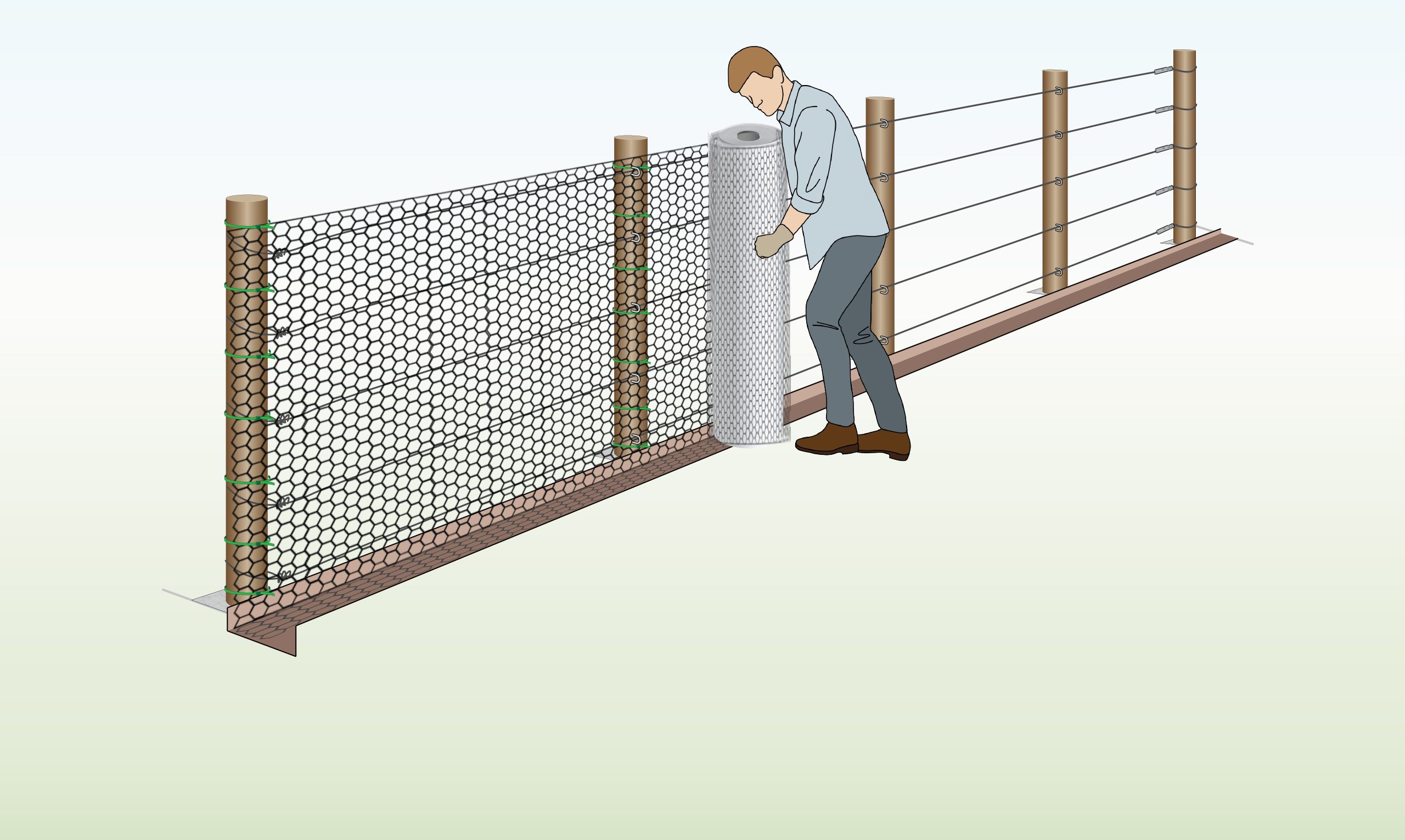

With T Posts

With Extra Security

| To Do | Explanation |

|

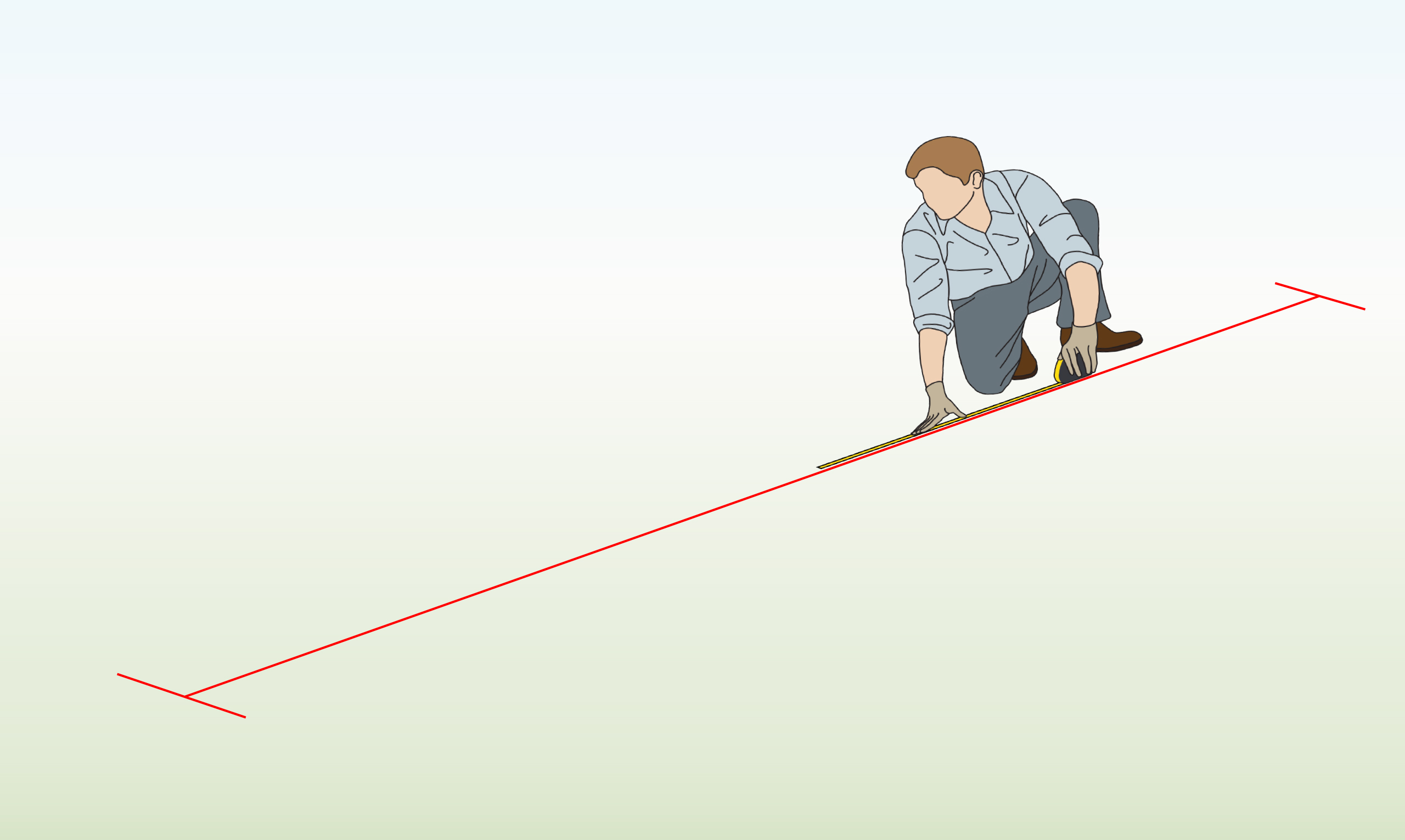

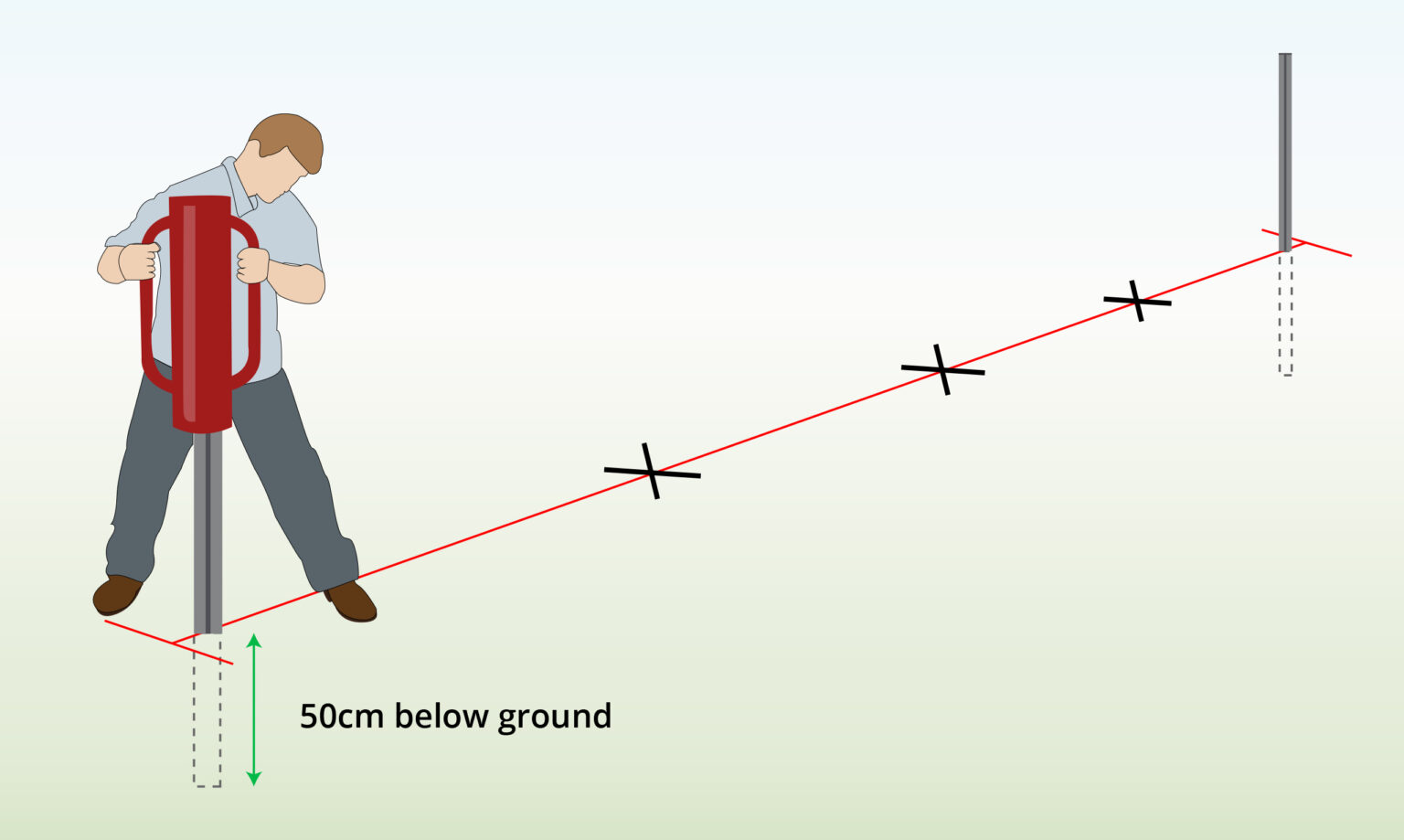

Step 1 – Mark Area

|

Create a straight line to mark the fence between the two end posts. |

|

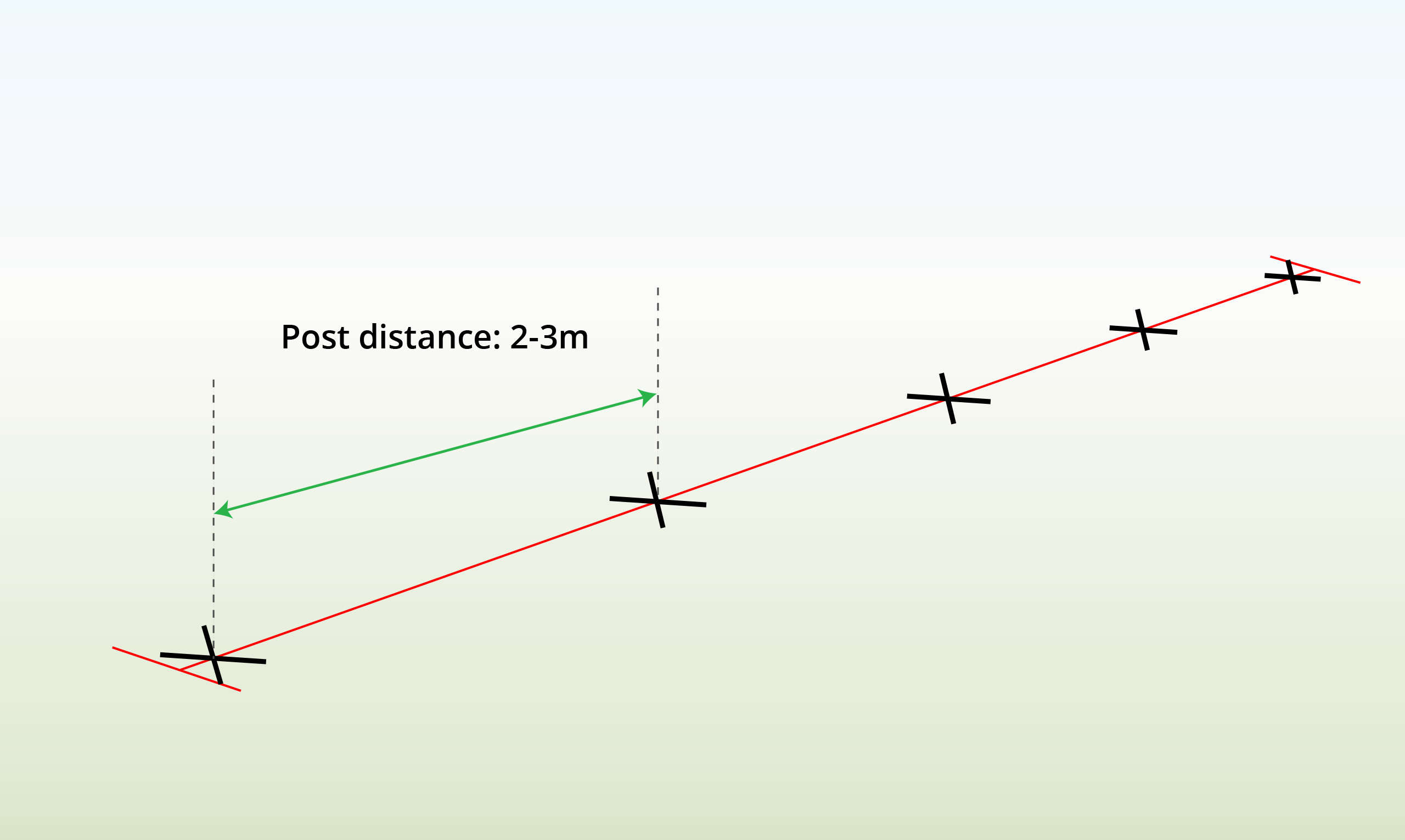

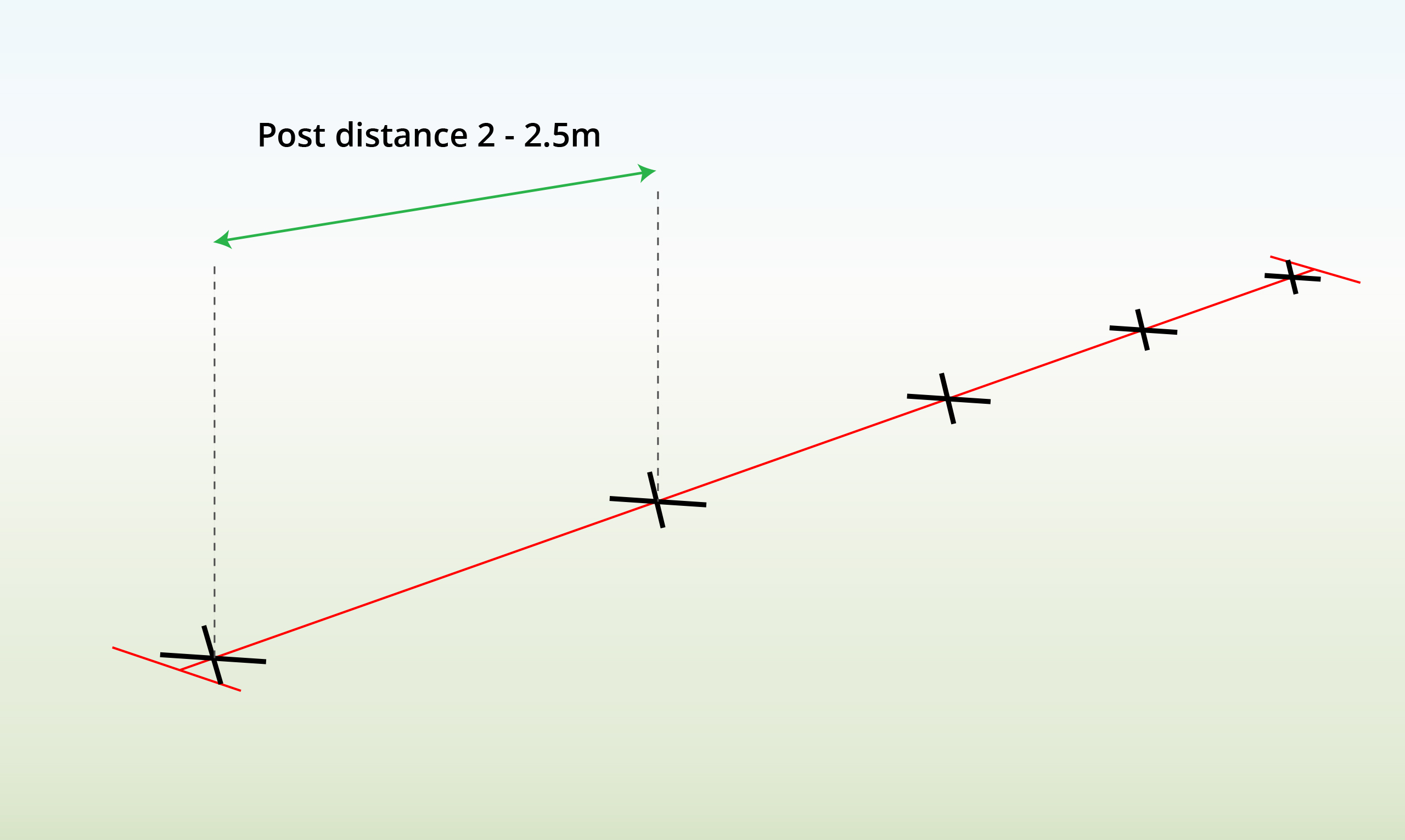

Step 2 – Measure Post Distance

|

Specify the post locations 2 -3m apart by using a tape measure.

For increased stability, reduce the spacing between your fence posts. |

|

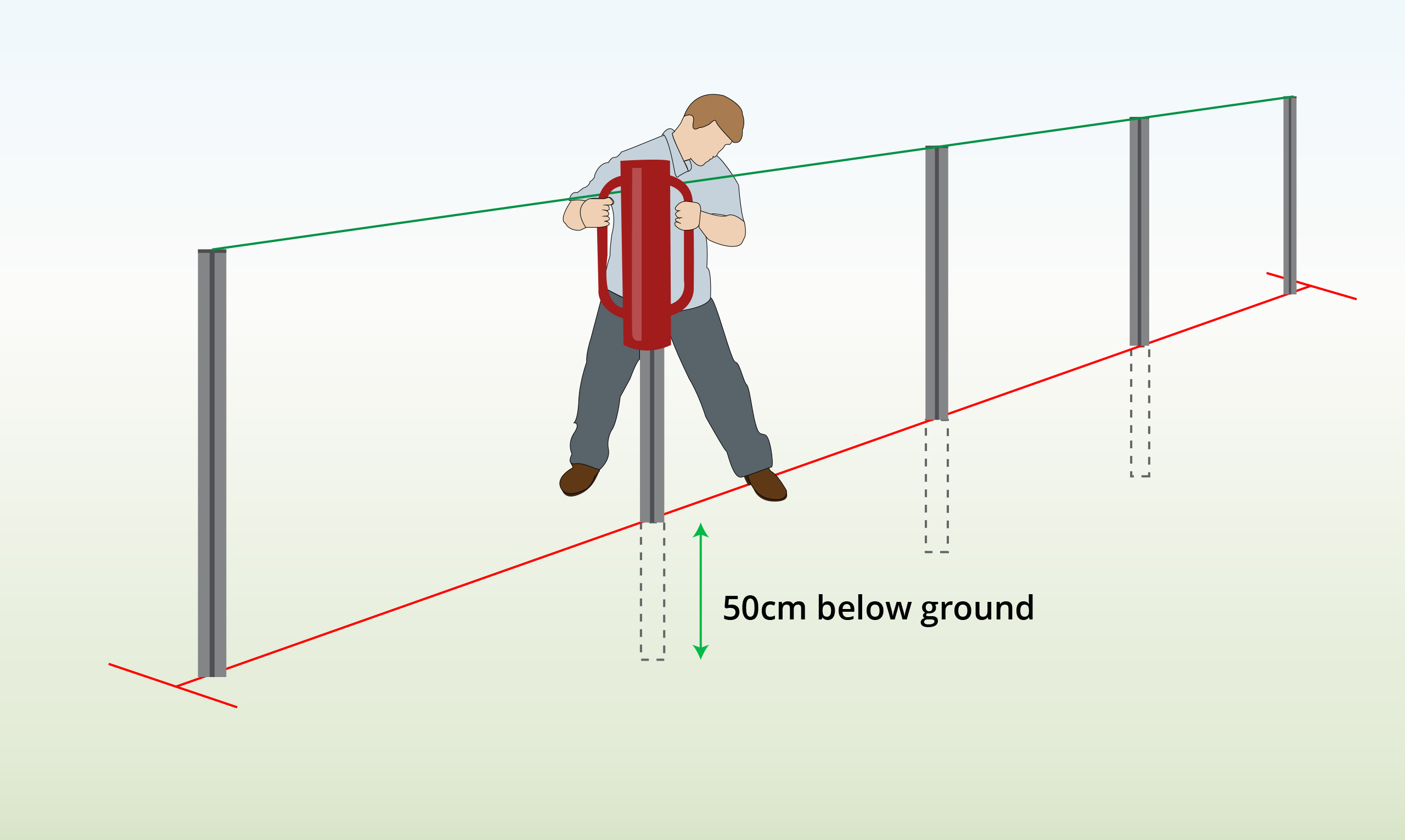

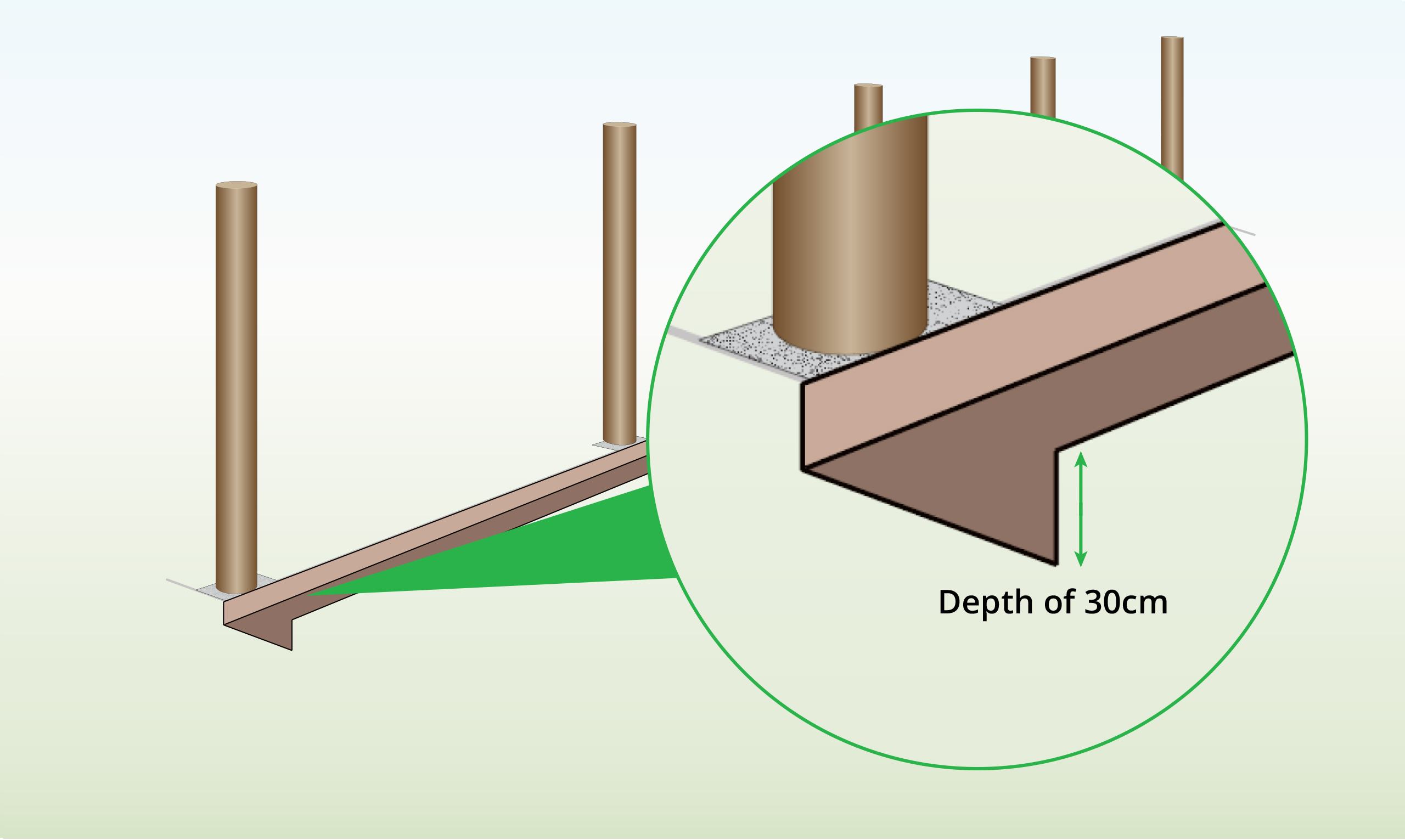

Step 3 – Install End Posts

|

Use a post driver or mallet to sink the end posts 50cm into the ground.

To maintain consistent alignment, make sure the holes of the posts are oriented towards each other. |

|

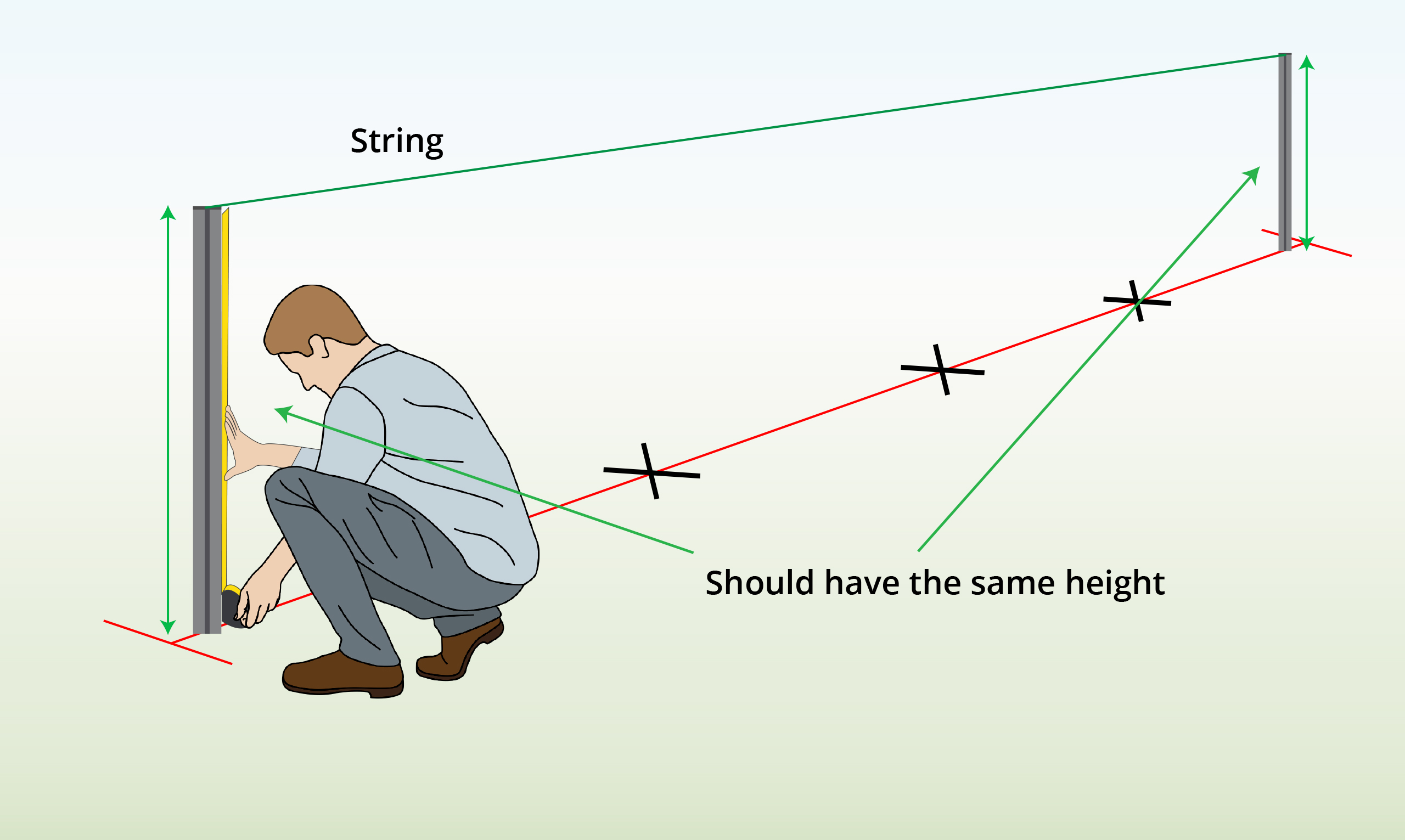

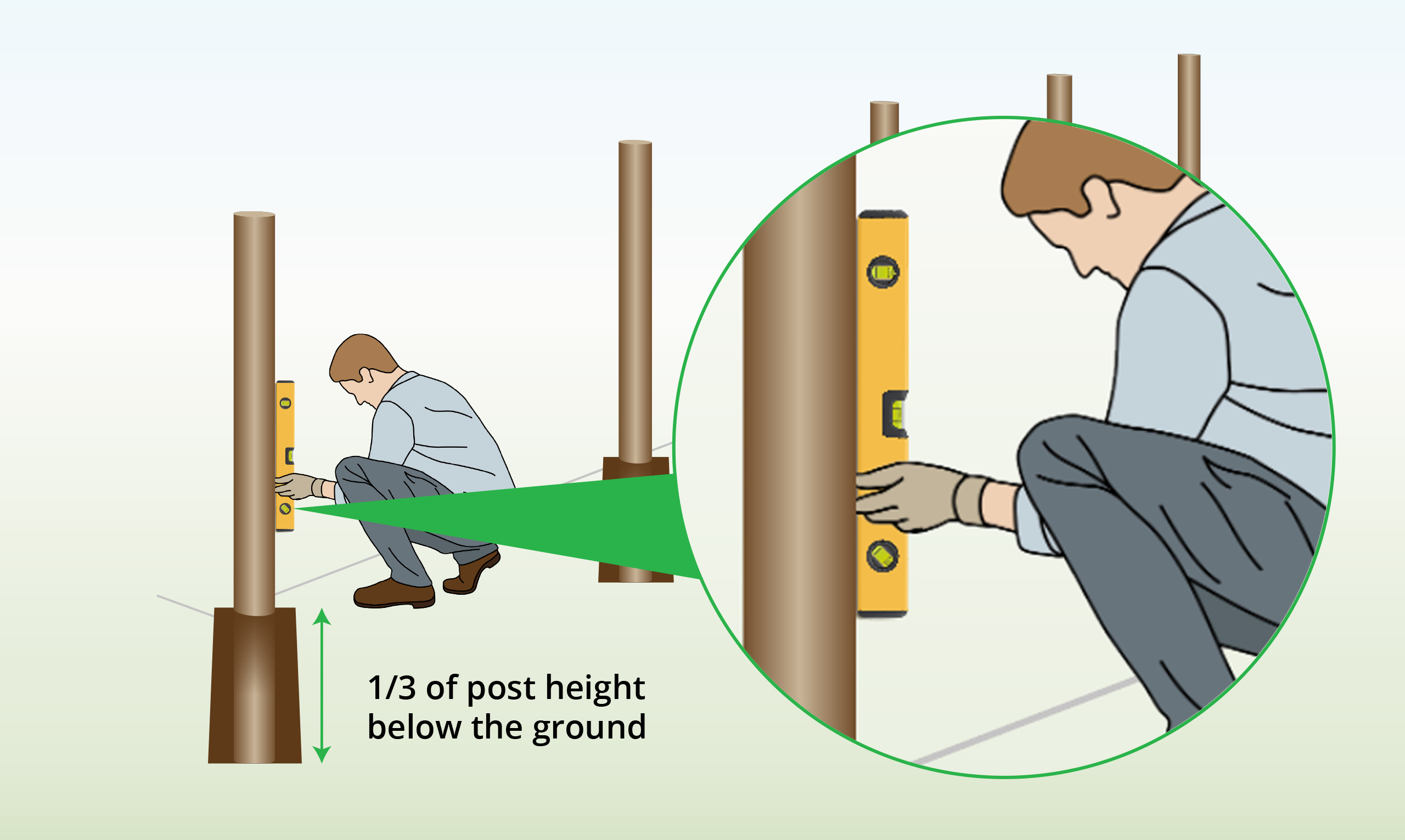

Step 4 – Check for Same Height

|

Secure a length of string between the end posts, and then verify that they have been installed at the same height by employing a tape measure. |

|

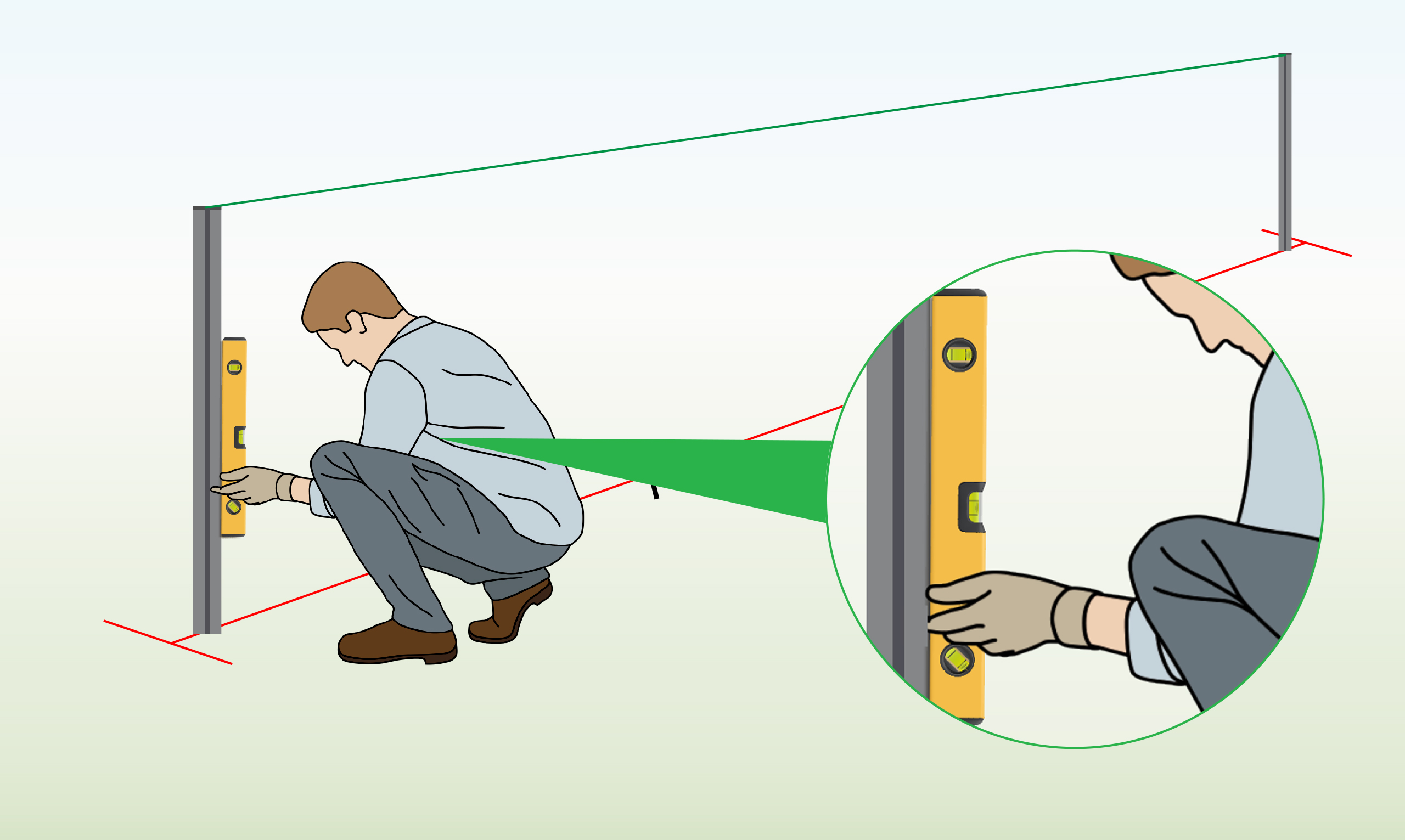

Step 5 – Check for Straightness

|

Utilise a spirit level to confirm that the posts have been set up perfectly straight. |

|

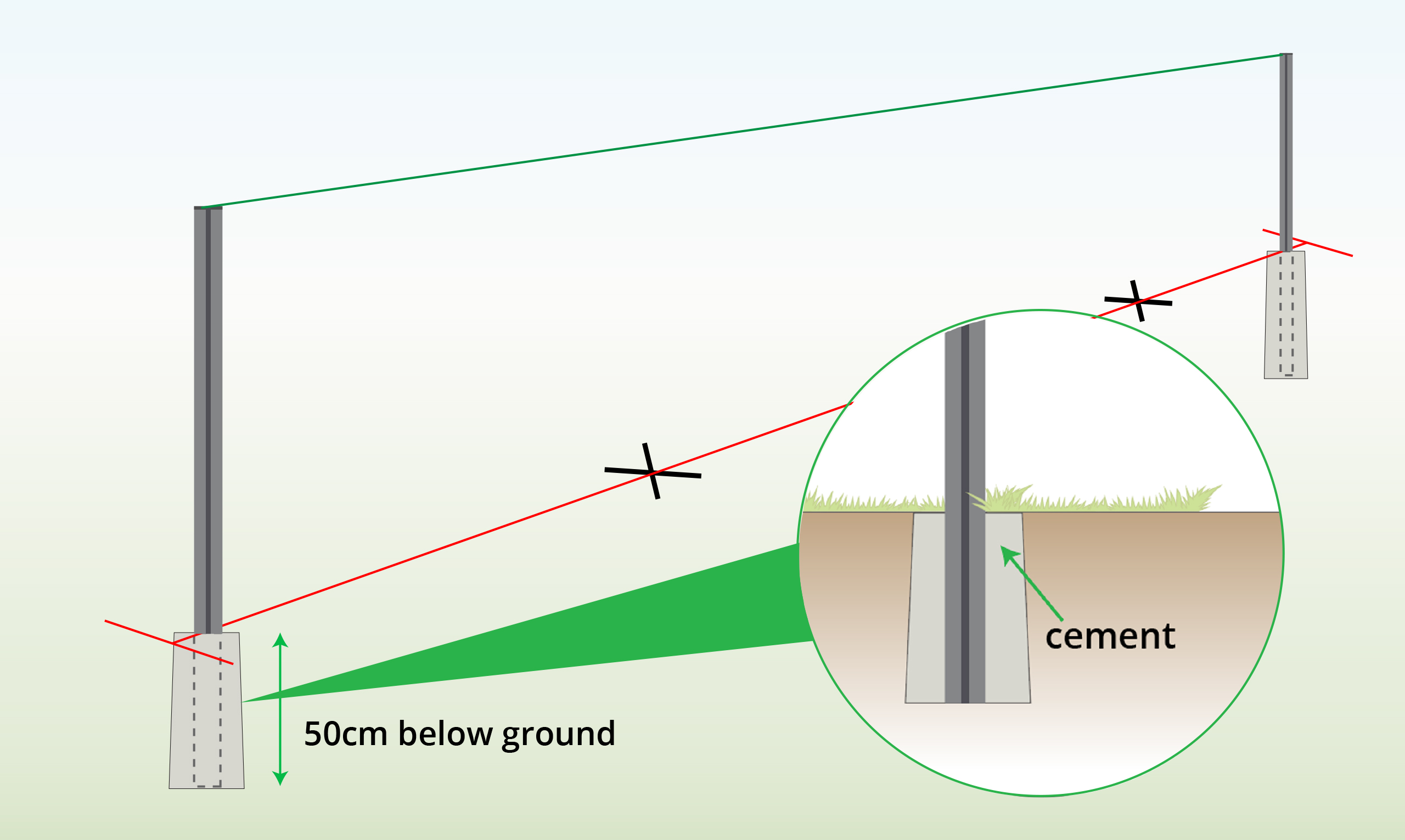

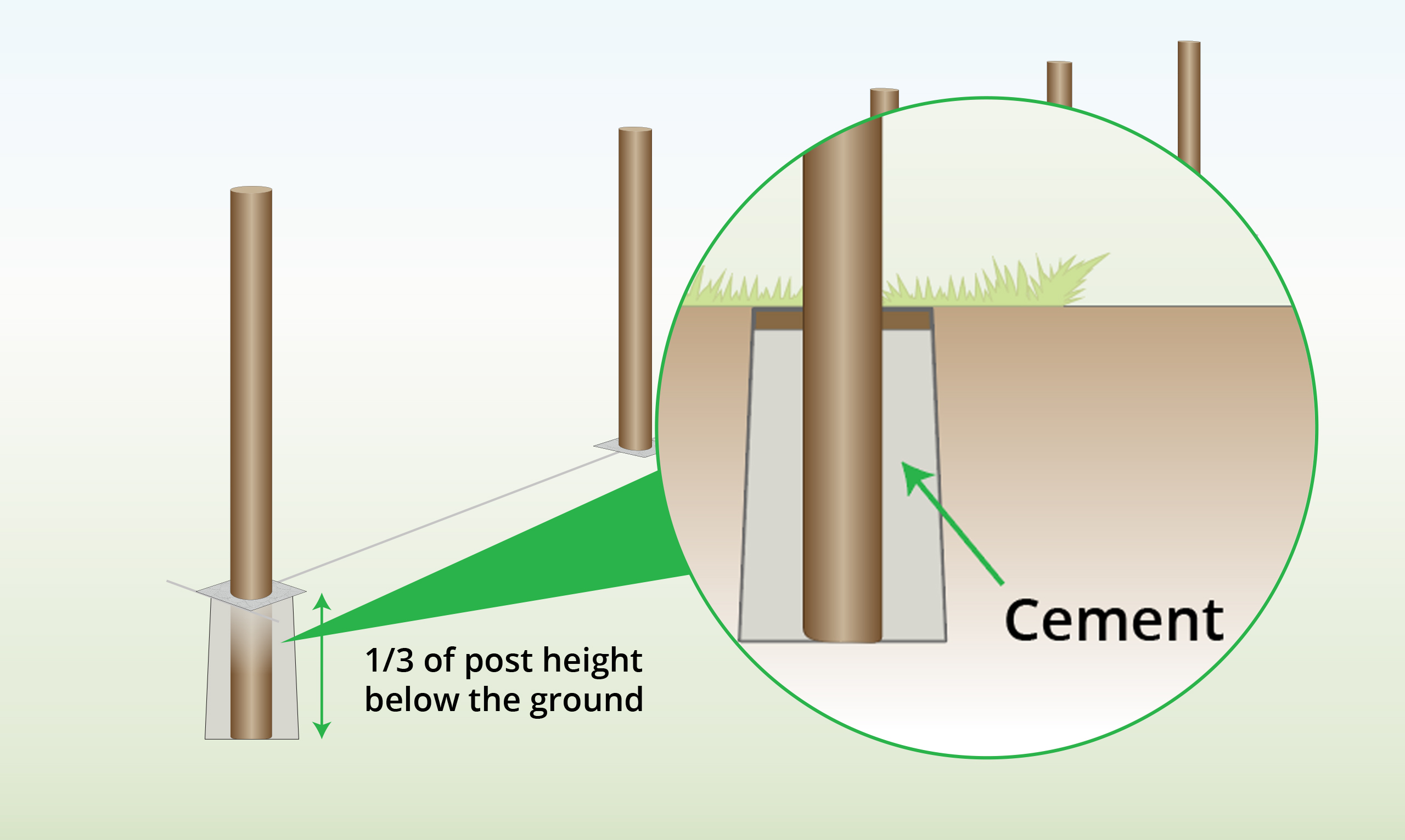

Step 6 – Set in Concrete (Optional)

|

For a stronger and more secure fence, anchor your posts in concrete. This involves digging a 50cm hole and pouring cement to provide a sturdy foundation for the posts. |

|

Step 7 – Install Middle Posts

|

For the installation of middle posts, repeat steps 3-6.

Ensure that the posts are oriented in the same direction and have been set up in a consistent manner, being both straight and at the same height. |

|

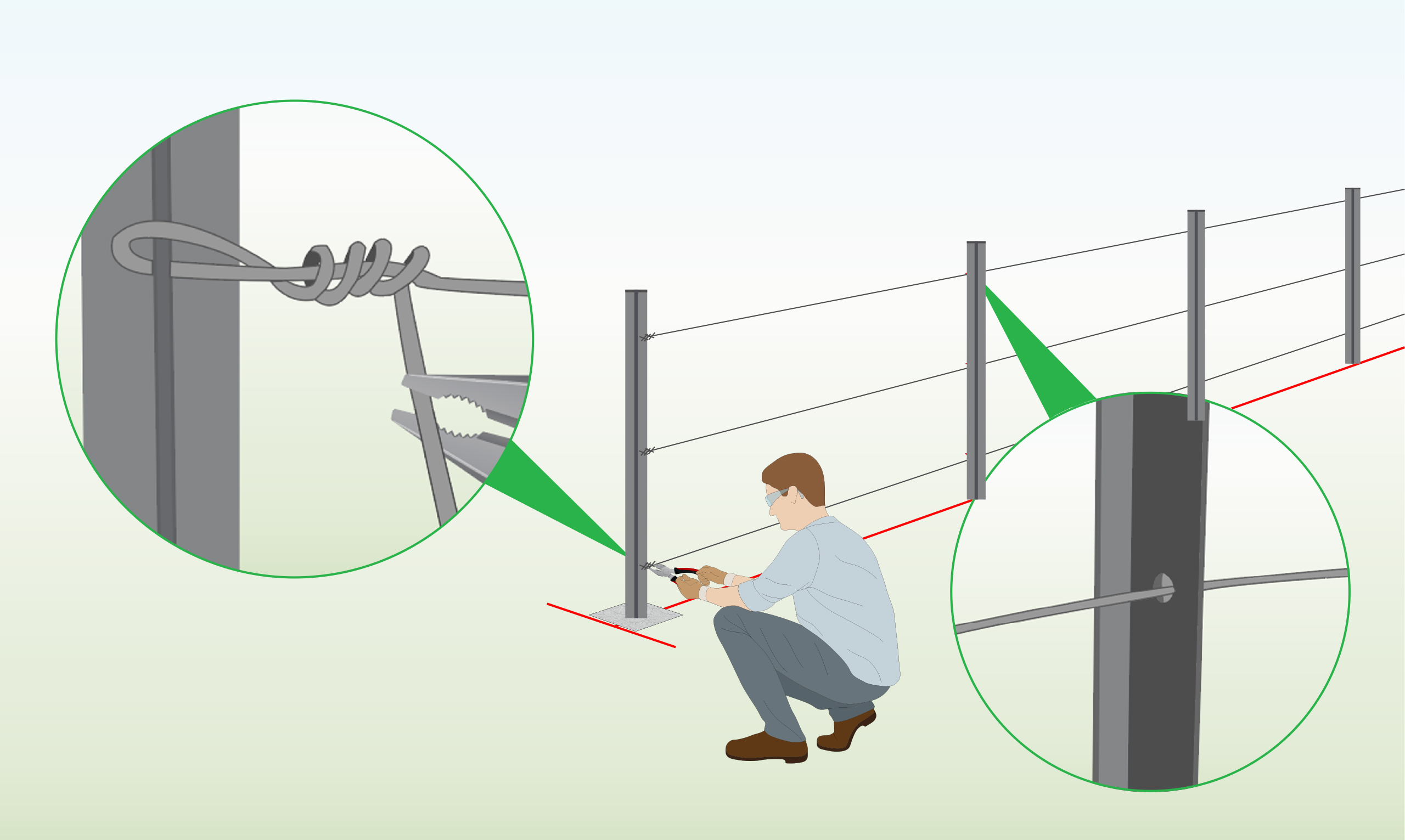

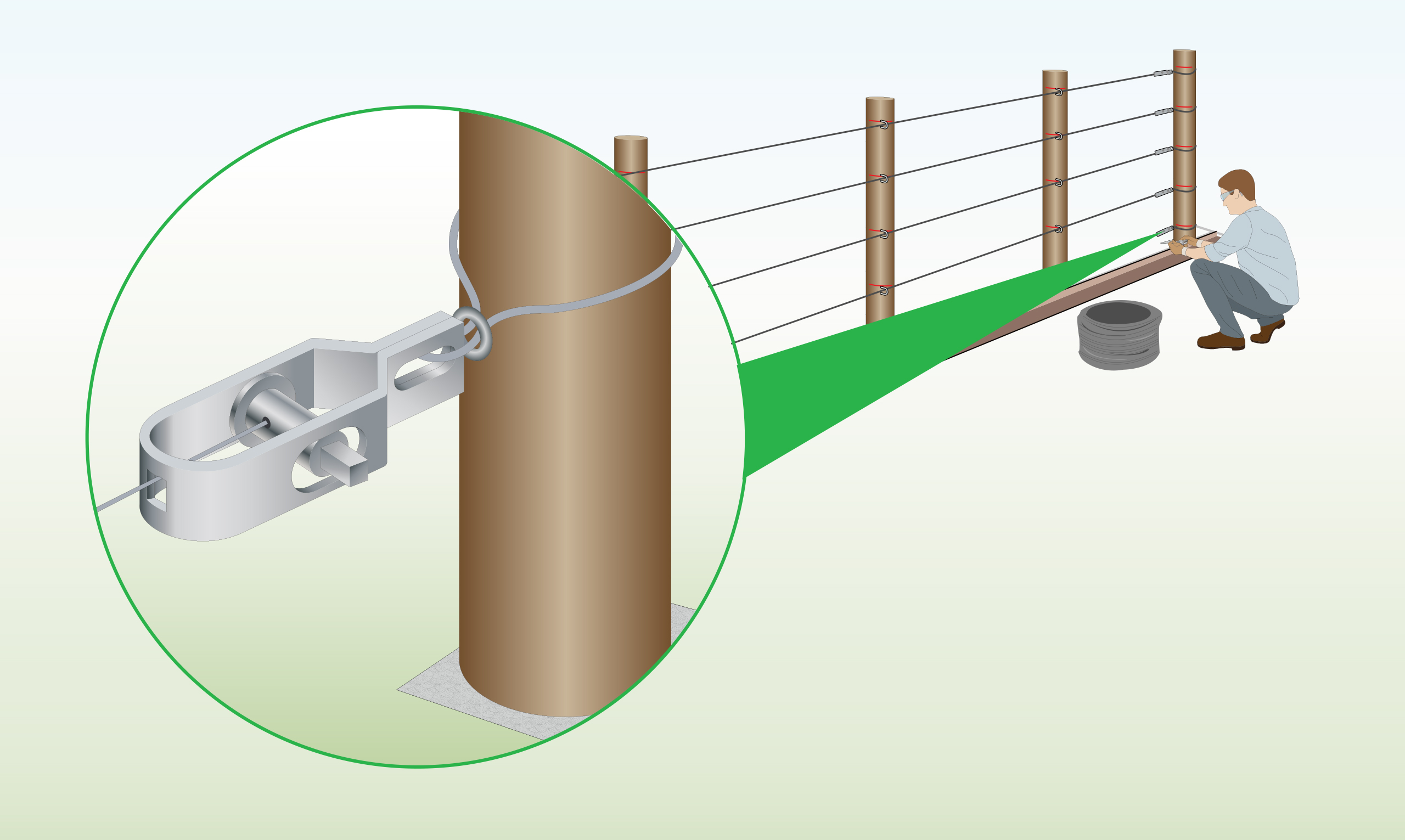

Step 8 – Install Tension Wire (Optional)

|

When using lightweight mesh, it’s advisable to secure a tension wire between the end posts to prevent any sagging.

Wrap the tension wire around the end posts’ hole and fasten it by twisting the wire’s end with pliers. |

|

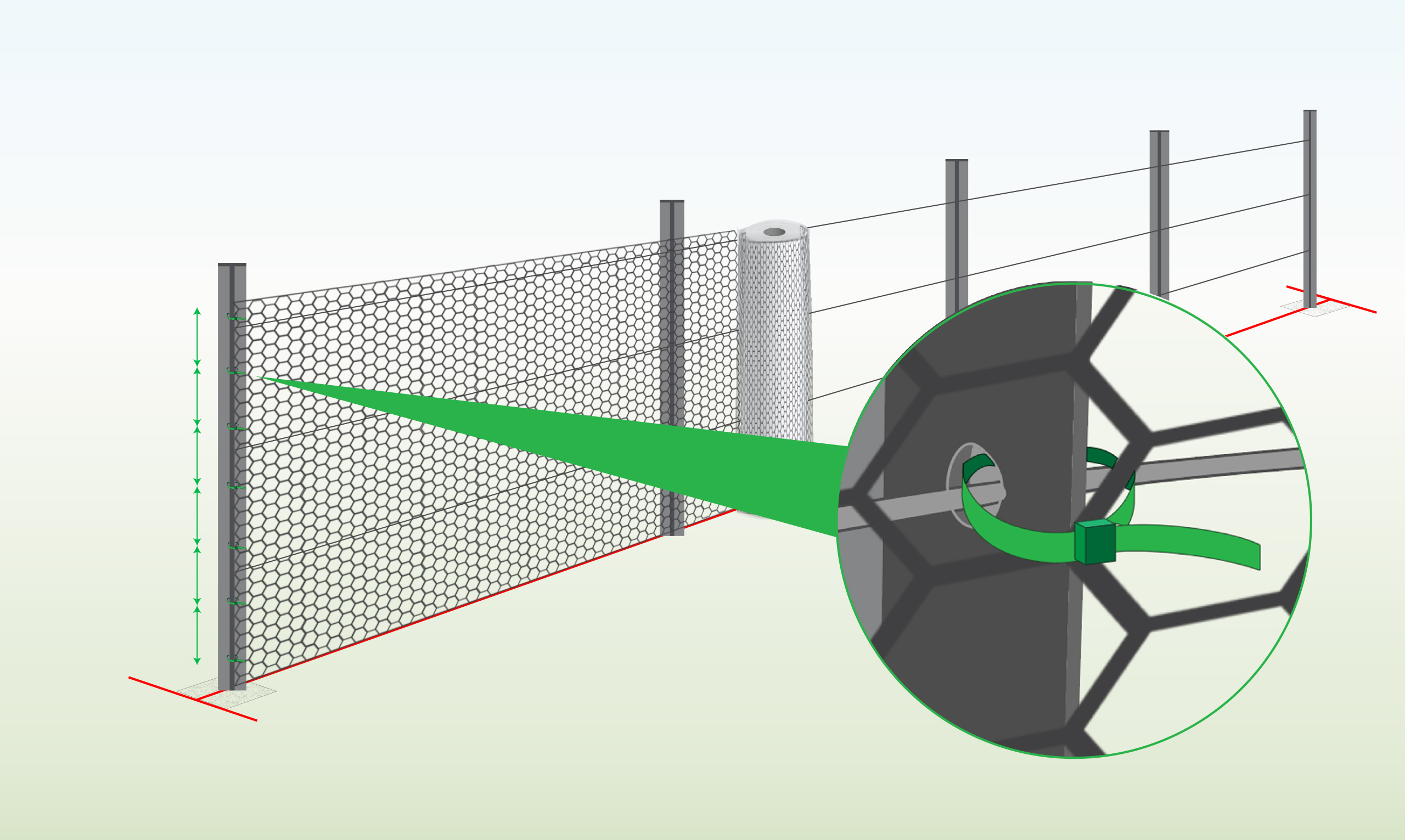

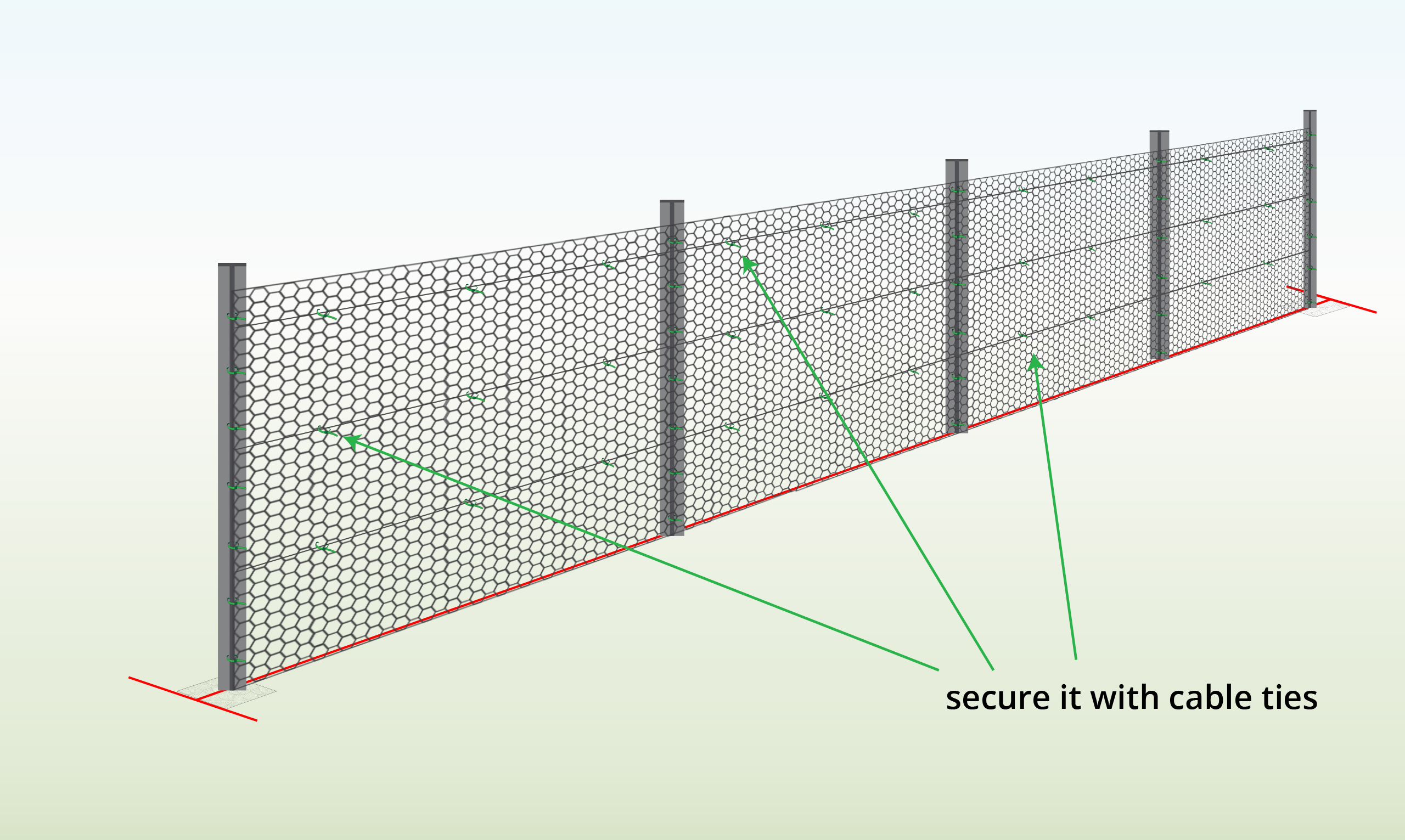

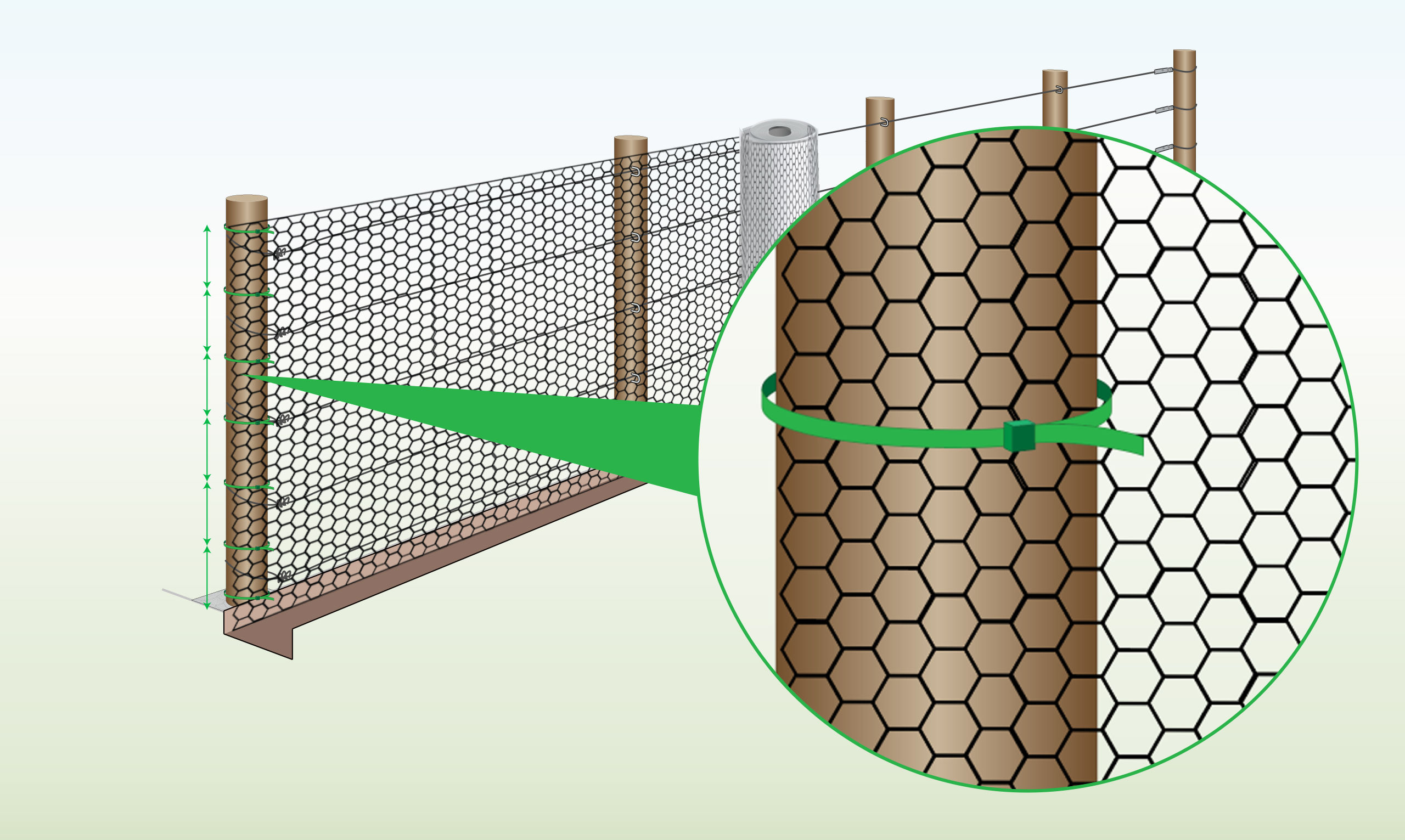

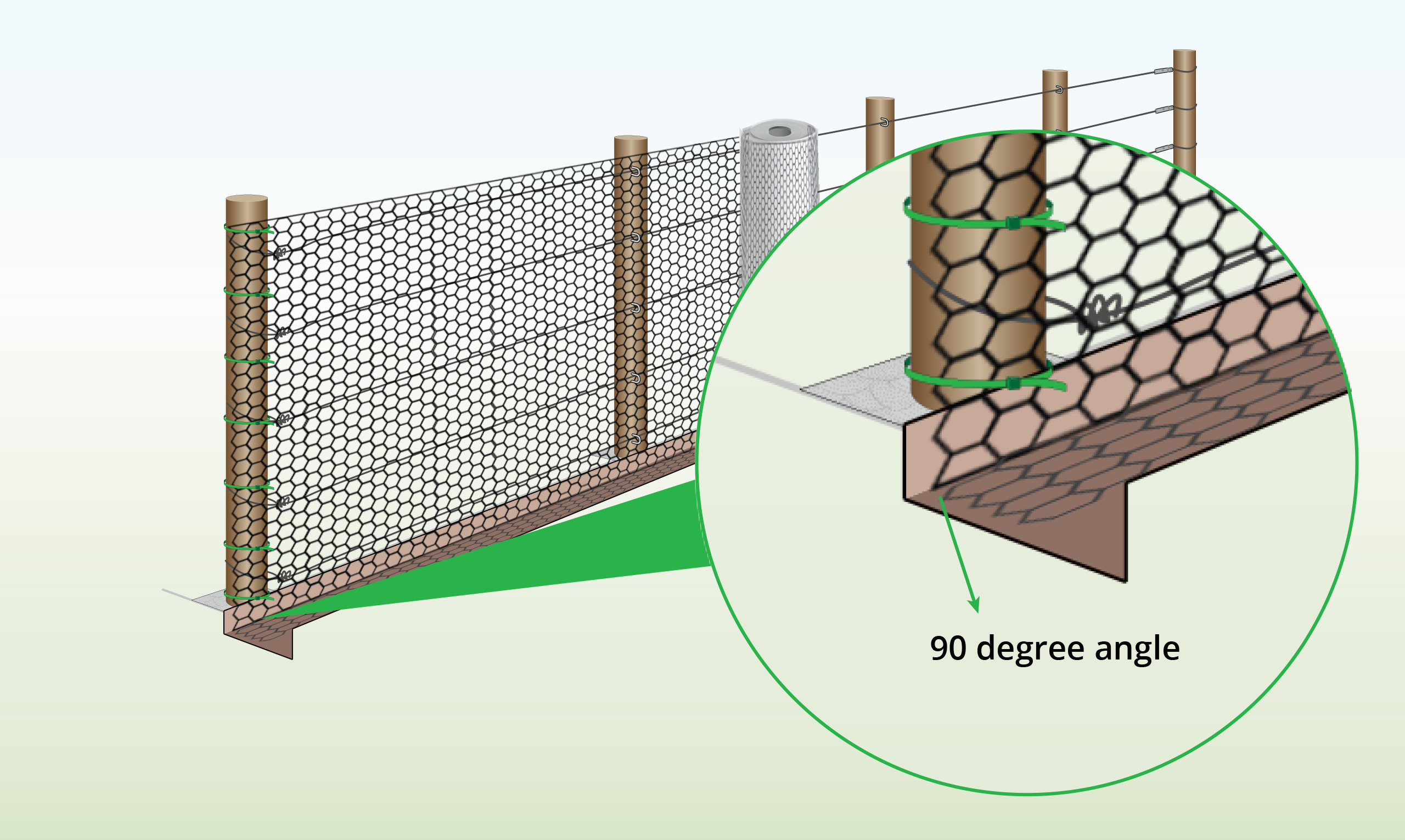

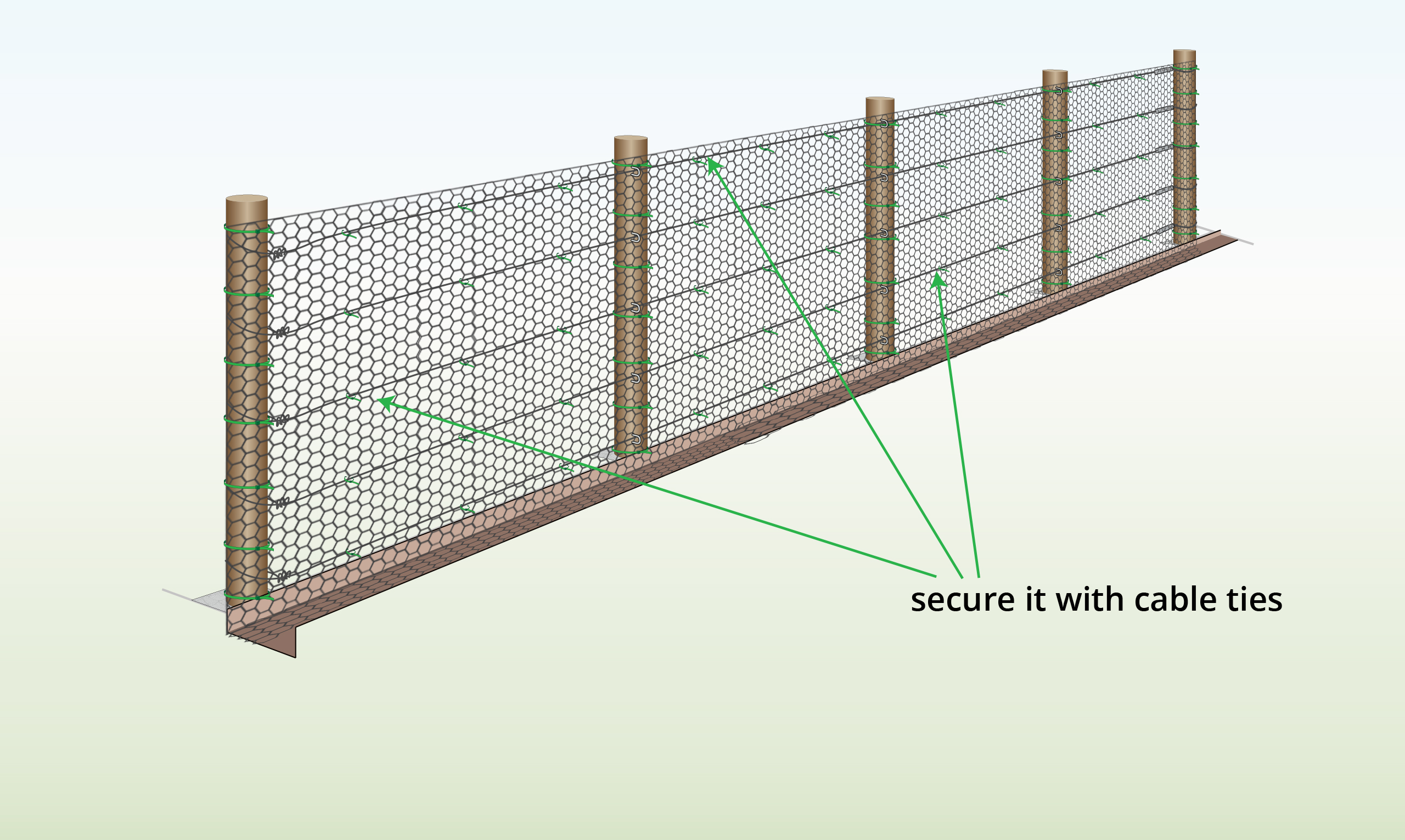

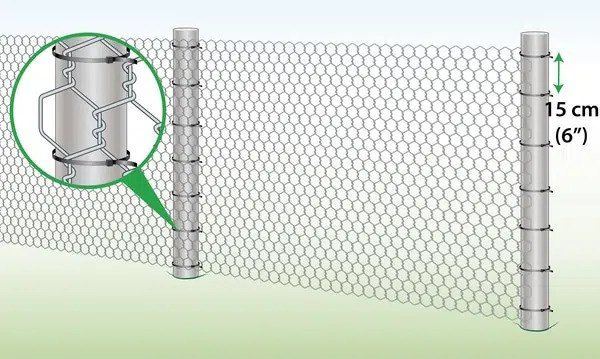

Step 9 – Attach Mesh to End Post

|

Fasten the mesh to the end post by employing cable ties, which can be threaded through the post’s pre-drilled holes.

You can increase the number of cable ties to encircle the entire post. |

|

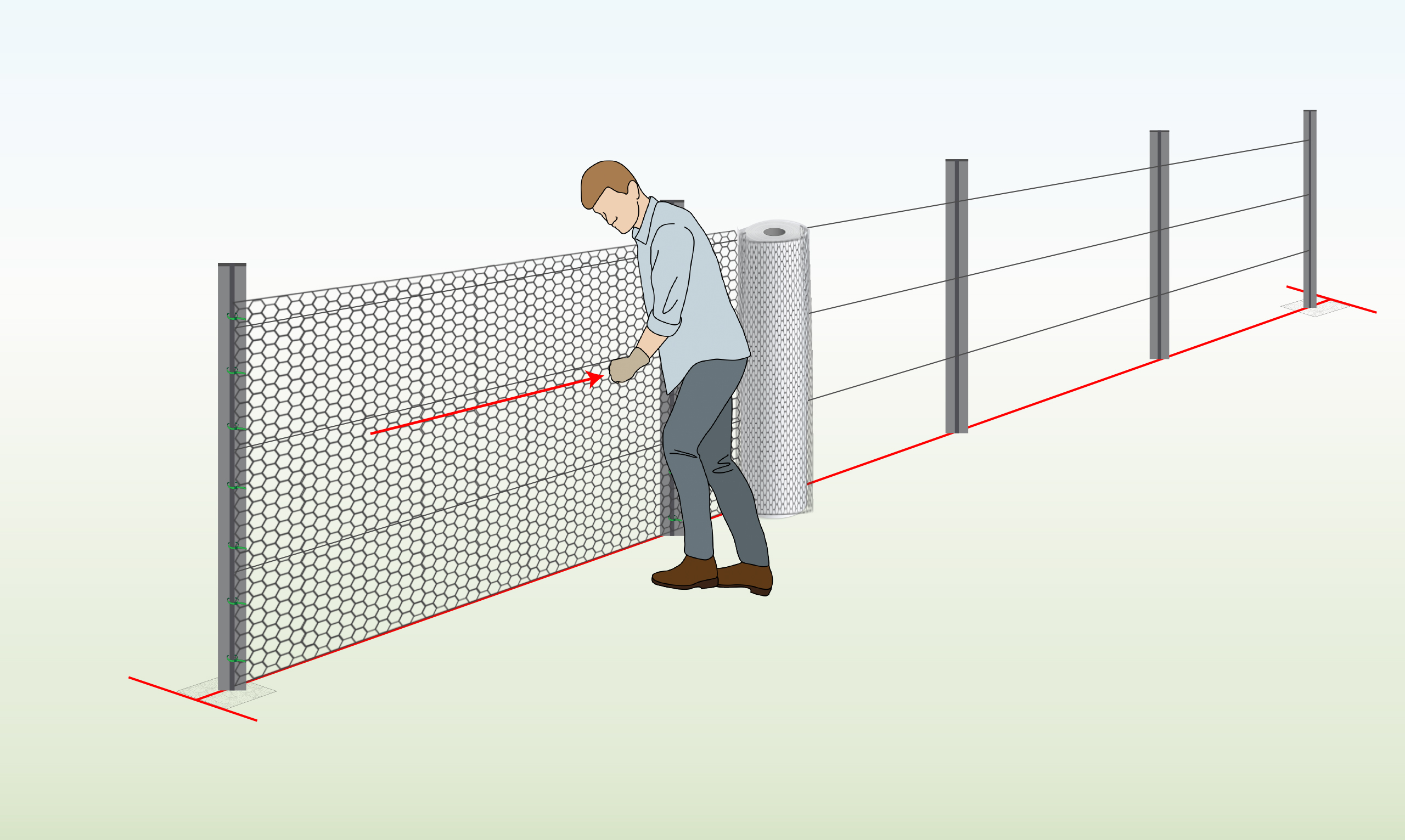

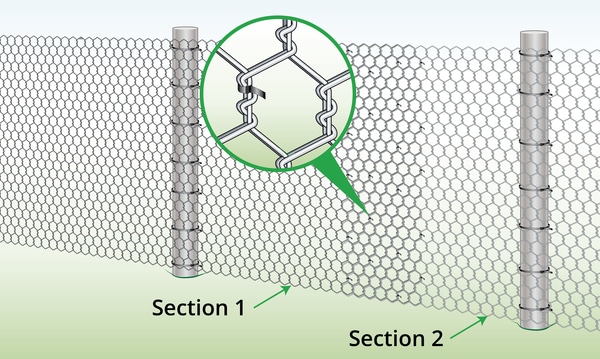

Step 10 – Pull Tight

|

Stretch the mesh firmly and then fasten it to the second post using cable ties. Be cautious not to pull it excessively tight.

Continue with this procedure until you reach the final end post. |

|

Step 11 – Attach to Tension Wire (Optional)

|

If you’ve installed a tension wire, fasten the mesh to it using cable ties, leaving approximately 30-45cm gaps between them. |

Attachments

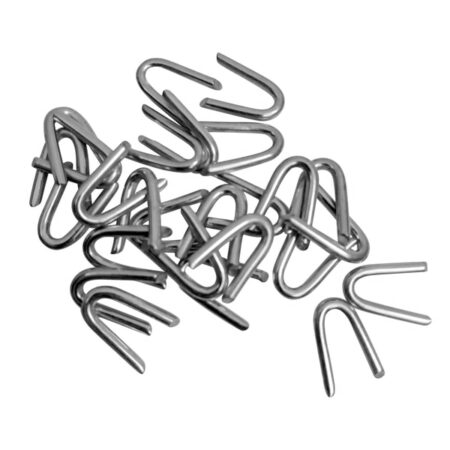

| Attach to: | How to: |

| Wood/ Wooden Posts (Staples) |

|

| Metal/ Metal Posts |

|

|

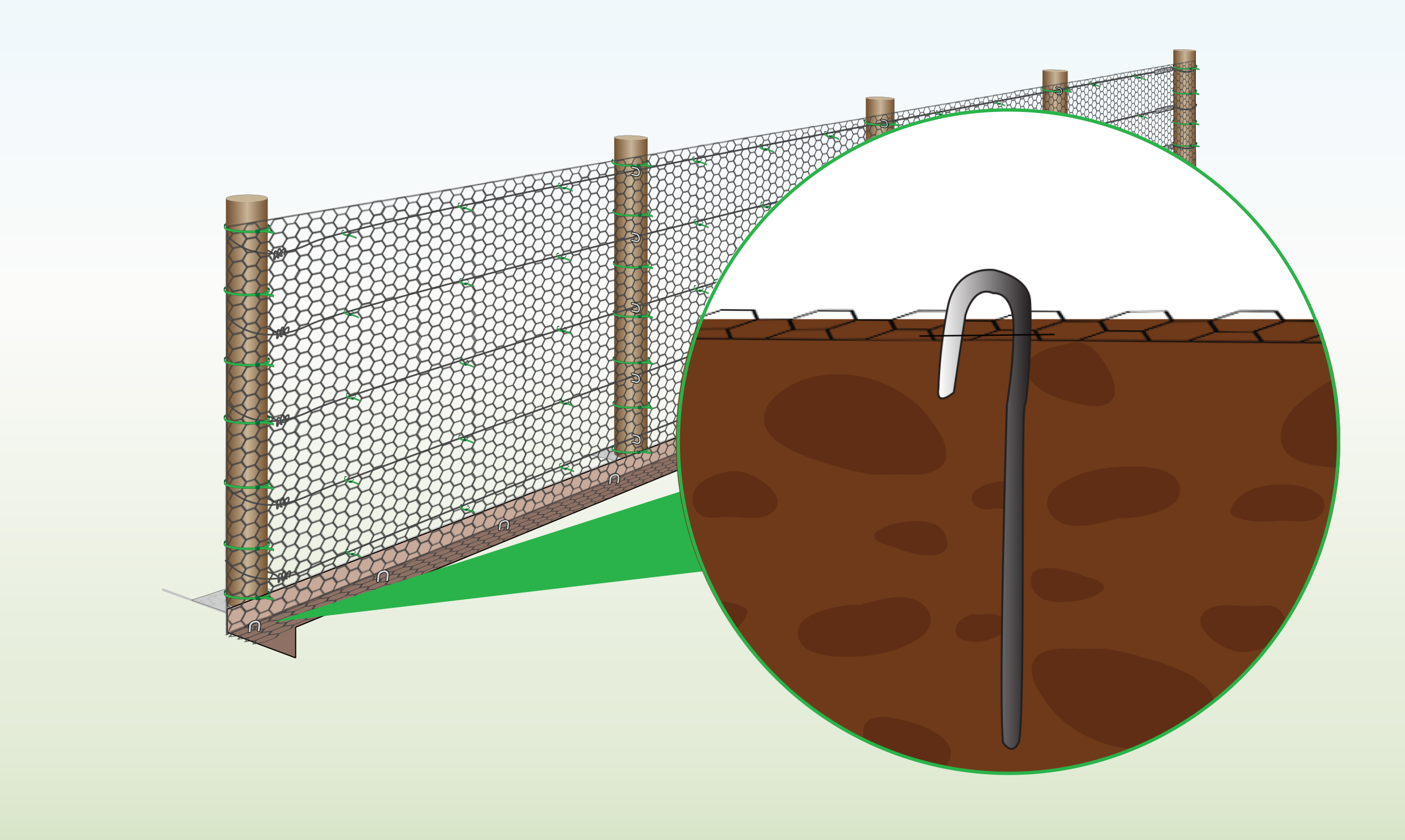

Soil (Pegs) |

|

|

Wire Fence |

|

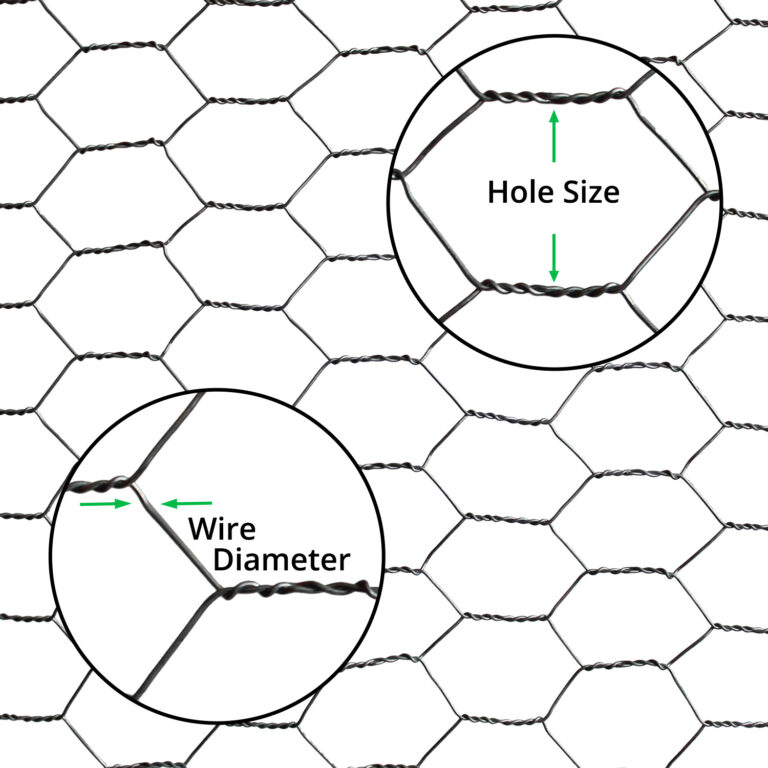

Gauges Explained

The diameter or thickness of the wire is referred to as the gauge (g.). The lower the gauge the thicker the wire.

Our chicken wire is available in:

- 18g. = 1.2mm dia.

- 19g. = 1mm dia.

- 20g. = 0.9mm dia.

- 22g. = 0.7mm dia.

FAQs

Can I use galvanised chicken mesh to protect my flowerbeds from digging animals and defecating cats?

Yes. We’d recommend the Super HDG option. Either attach it to posts and surround the flowerbed, or lie the netting flat on the soil and cover with dirt. Once detected by the animal it will likely stop digging.

How do I attach the mesh to my coop?

- Unravel the netting and use a pair of pliers/cutters to create the desired length.

- Wearing protective gloves, fold about an inch of the netting over at each end to avoid sharp edges that may harm your birds.

- Use a staple gun to attach the netting to posts, or to the outside of your coop.

Downloadable PDFs

Specification

- Economy Chicken Wire Specification

- Standard Chicken Wire Specification

- Super Chicken Wire Specification

Installation

Guides

- How to Paint Chicken Wire

- How to Make Tomato Cages From Chicken Wire

- How to Make Chicken Wire Ghost Figures

- How to Make Topiary Frames with Chicken Wire

- How to Make Flower Vase with Paper Mache

- How To Attach Chicken Wire to Wood Frame

- How to Make Picture Frames with Chicken Wire

- How to Make a Christmas Light Ball With Chicken Wire

- How to Use Chicken Wire in Flower Arrangements

- How to Make a Jewelry Holder with Chicken Wire